|

| Shindos modified cartridge, based at the famous Ortofon SPU-A |

Today I am following on to describe Mikes Verdier-Shindo-chain already featured in my last article. I did describe Mikes tremendous care taking about any little detail having influences to the final performance of his set audio up. Since almost 30 years he does have struggled hard with the progression of tiny steps of improvements within his personal audio chain, always interrupted by setbacks from missing estimates and irritated by wrong conclusions. If you have an idea for what you are looking and if you don't expect the easy way of "pluggable components from the land of milk and honey", than you will have the correct prerequisites to build up a audio chain able to perform within a higher degree of harmonic properties. Instead of solely ingenious technical comprehension, a solid portion of common sense, consciousness, experience, sensitivity and refined spirit, will be the major properties to extend such a performance into real life instead of stunning superficiality of HiFi.

|

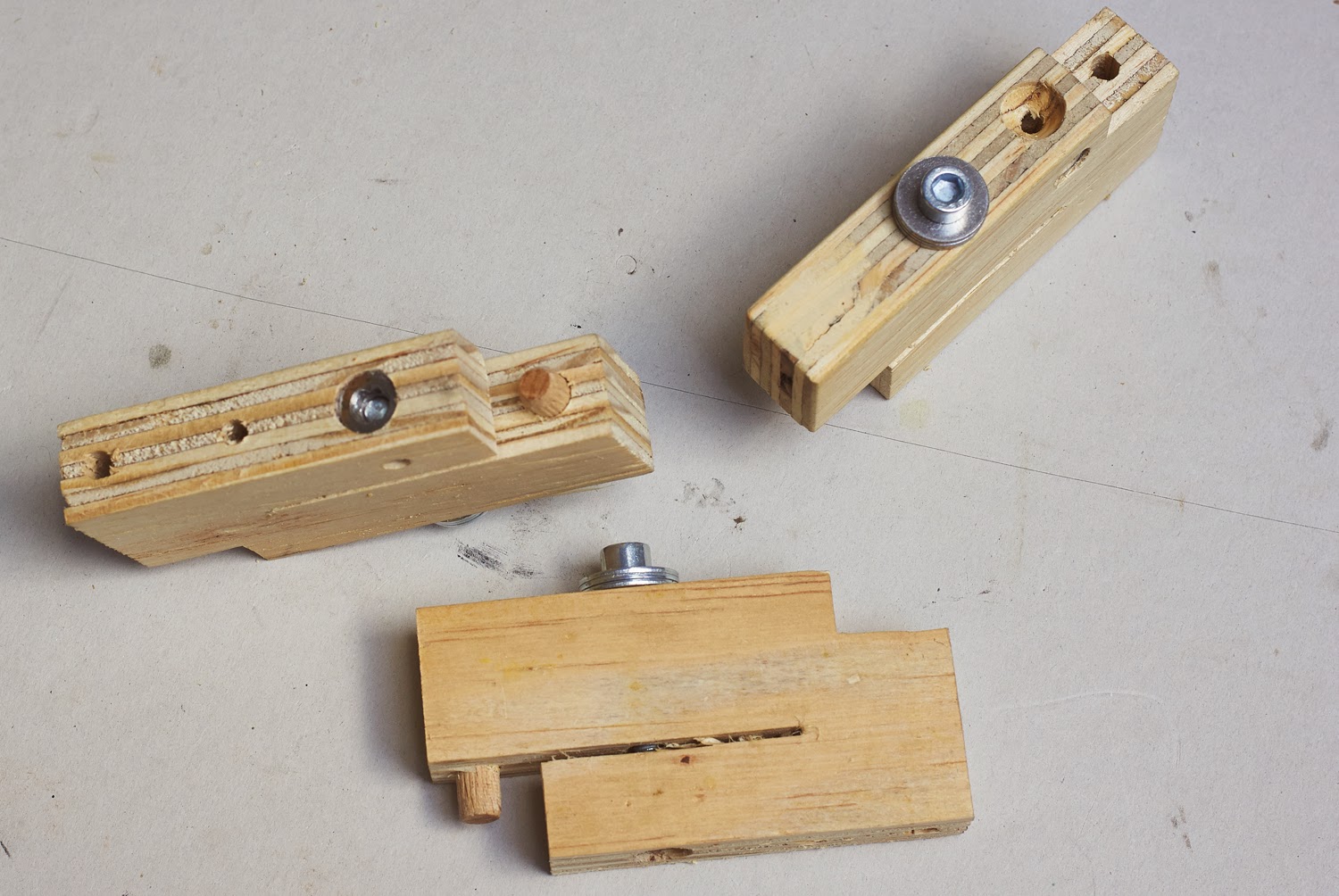

| Wall panels fixed with special wooden washers to the underlying construction, at the left additionally covered with quilted fabric |

Mike did once line out his listening room with a highly complex structure of massive wooden panels in order to create a similar effect. A solid support frame from pine pales dowelled to the massive brickstone wall is the under construction to take layers of long wooden panels. Each panel is fixed with several wooden washers to the underlying frame. Within this construction it is possible to keep each panel movable and fixed at the same moment, in order to take out the best portion of energy, reducing high amounts of reflected waves. Very important areas of that wooden lining are covered additionally with quilted absorbent cotton tissues, like the ceiling area above the speakers. When I do remember right, Mike did spend several month only with evaluation of improvements coming from different wooden linings in his listening room, before he did set up his audio components for listening.

A completely different stage of refinement can be archived with controlling the raw electrical supply conditions. The electricity as it is supplied by the local distributors, is generally not free from high frequency detorations and peaks arising from high energy switchings of industrial production or traffic.

A early pretransforming process together with a hf-filtering effect can be archived with huge variacs for the line voltage adjustment. Mike has built for this reason a variac switch box, were all his audio components are supplied with smooth electrical input.

|

| Switch box with variacs for the complete audio system |

From my point of view a well working audio chain is able to show a bunch of properties beside nice sound. It should be able to transport the inner and outer structure of music without any tiring of the attentiveness to the listener. Such a set should be able to show its physical abilities with a foremost dynamic performance and refined harmonic subtlety, in short a almost natural modest behavior instead of intrusive superficiality. Commonly this sort of superficiality is connected to a definition of "HiFi", were always more is equated with the term better, a typical value scale of commercially marketed products. But when "more"will be substituted with a more complex internalized and subtile listening experience, were the reference is set close to natural acoustic instrumentations within real music, it can be clearly experienced, that such a performance in a foremost stage depends on absolute contrary properties than such superficial effects. A advanced performance with a more unobtrusive manner without any effects, need a higher degree of conviction work in sales processes, its success depends mainly on positive experiences made with well made products, together with comprehensible presented arguments. Both are elapsing scarce goods in todays commercial audio world and its distribution culture, continuously opening a gap which is merely closed from magicians, bag thieves and from gossip in web communities. A development which makes a tremendous turning to vintage audio products from the "golden years" comprehensible. This process started at the decline of audio development in the 1970ties and is still growing, even when Ebay has already cleared off the cellars of the western world during the last decade. Within this routine lots of vintage audio products have been washed up to regions, were these originally never have been part of the market. In the former Warsaw pact countries a grown interest into the not available myths is obvious, as all far east countries are now in the race to catch up with Japan and Korea as pace setting nations for more than 40 years in that field. Now Hong-Kong and Singapore, both in a economic advanced state, seem to overtake the main investments into vintage audio products and seem to be the spearhead of its final end. In the originating countries of this culture, as in the from western ideals dominated consumer culture, the ideas of storage less cloud streaming and equipment exempted listening of audio to go have turned the wheel of "progress" into nirvana.

|

| The LM22A/555W combo with LM597 high frequency field coil driver underneath, decoupled by a spring suspension system |

Since two years now Mike harvests the fruit that he has sown over decades in his own audio history. Before that stage, he was in a permanent process of search and exchange, I think a lot of yours will know what is being meant with that phrase. Caused with the acquisition of the big medium frequency horn units, all positive advantages of his before summarized components are adding up to a higher degree of fidelity. The key was the Line Magnetic LM22A with LM555W field coil driver, which makes a physically advanced perception of audio possible, like no other principle. It can be seen more like a music instrument than as a receiving and transmitting device. A two inch diaphragm made from thin foiled aluminum, with quite movable surrounding, in a field coil operated magnetic case, amplified through a almost 2 meter long horn development through a 0.75 x 0.75 meter sized opening, which performs the frequencies from 300 to 7000 hertz, is not only a rare and unique audio transducer, it is physically working like a music instrument on its own. The radiated waves distribute air very similar to a common known instrumental brass horn. The human male voice as tonal scale, a bass trombone, a cello and a tenor sax perform almost the same frequency range, seamless covered by this outstanding audio transducer. Like these original voices, it is able to release its radiated energy with a comparable ease and in a unconstrained manner, since its length of development and its minimal moved diaphragm weight. Comparing this weight to a 8 inch paper cone, it is just a tenth of its moved mass and this fact declares the outstanding dynamic properties and its inherent low distortion properties.

|

| Basic physics lecture: horn mouth sizes and dedicated frequencies, I think this figures are very gracious valued comparing the real. |

|

| Original drawing from Western Electric from the 1930ties. |

|

| LM597 field coil high frequency horn on top of WE inspired dipole enclosure with Klangfilm KL405 woofers |